Description

Key Features:

- Material and Build: The stud features an aluminum alloy metal shell capable of withstanding over 30 tons of pressure, making it suitable for installation in high-traffic areas such as the middle of roads. The design includes sunken reflectors within the aluminum shell to protect them from damage when driven over.

- LED Lights: Uses high-brightness American brand LEDs that have a working time of approximately 100,000 hours.

- Solar Panel: Equipped with a USA brand solar panel with a 22% high conversion rate, ensuring efficient and fast charging.

- Epoxy Resin Glue: Uses high-quality epoxy resin glue for secure installation, which guarantees that the solar studs are firmly fixed and capable of charging efficiently.

- PC Board: Incorporates a Philips PC board known for its safety and stability, ensuring long-term reliability.

- Load Capacity: With a load capacity of more than 30 tons, these studs are designed to be installed in crucial areas like highways and can withstand the pressure from heavy vehicles.

Working Principle:

- Energy Conversion: The solar panels absorb sunlight during the day, converting it into electrical energy stored in the stud’s internal batteries or capacitors.

- Automatic Illumination: With the onset of dusk or inclement weather, the stored electrical energy is automatically converted into light energy through LEDs. This process is controlled by a photoelectric switch that activates the LEDs, which then emit a bright, flashing light.

- Visibility and Safety: The emitted light significantly outlines the road better than conventional road studs, providing earlier visibility to drivers and hence reducing the chances of accidents.

Installation Method:

- Distance Marking: Mark the installation spots carefully on the road.

- Drilling: Use a Core Drill to create holes of Φ35mm diameter and 55mm depth where each stud will be placed.

- Cleaning: Remove all debris from the drilled holes.

- Epoxy Application: Pour epoxy into the holes as per the manufacturer’s instructions.

- Stud Placement: Insert the solar road stud ensuring the lighting surface is set at the desired viewing angle and the epoxy adheres properly without any gaps.

- Curing: Allow the epoxy to cure for 6-8 hours, after which the installation isolation can be removed.

Recommended Spacing:

- Highways and Expressways: Approximately 5-6 meters (7-8 yards).

- Dangerous Entrances and Exits: Approximately 2-3 meters (4-5 yards).

- Hospital and Parking Lot Access Points: Approximately 0.5-2 meters (0.5-3 yards).

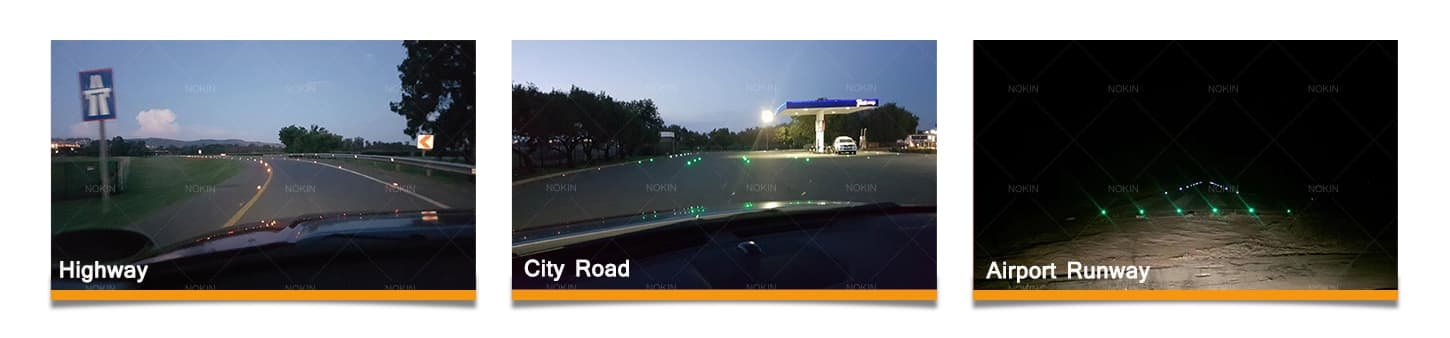

Applications:

- Wide Applicability: Suitable for motorways, urban roads, parking lots, and other public places where enhanced night-time visibility and road delineation are required.

Solar Road Stud Specification :

| Body material | Aluminum(GB-ADC12)+PC(Japan Brand) |

| Power supply | USA Brand High Efficient Solar Panel 2.5/150MA for NI-MH battery 5V/60MA for Lithium battery |

| Battery | NI-MH1.2V/600MAH(high temperature resistance, Made in China) Lithium battery3.2V/500MAH(Made in Japan) |

| Water proof | IP68 |

| Visual distance | >800m |

| Life span | 2years for NI-MH battery; 5years for Lithium battery; |

| Load capacity | >30T(can be installed in the middle of road) |

| Size | L125mm*W107mm*H26+50mm (L4.92″*W4.21″*H0.98″+2.17″) |

| Package: | (without spike): 2pcs/box; 60pcs/ctn; Weight: 28kgs; Carton size: 67.5*28*20cm (2pcs/box; 60pcs/ctn; Weight: 61.73bs; Carton size: 26.57″*11.02″*7.87″) (with spike):1pcs/box; 45pcs/ctn; Weight: 30kgs; Carton size: 66.5*44*28cm (1pcs/box; 45pcs/ctn; Weight: 66.13bs; Carton size: 26.18″*17.32″*11.02″) |

Reviews

There are no reviews yet.