Description

Description:

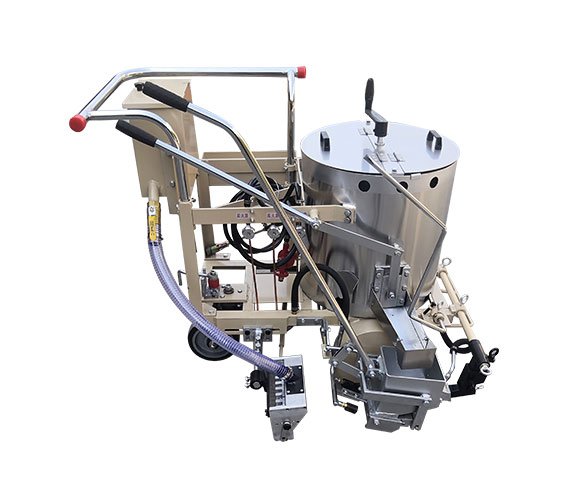

The thermoplastic road marking machine is crucial for developing thermoplastic marking lines, mainly used in conjunction with a hot-melting kettle. This machine is favored for its straightforward operation, ease of transport, and minimal maintenance requirements, making it ideal for both new projects and maintenance of existing markings.

Main Features:

- Precision Cast Iron Scribing Bucket: Ensures that the lines are straight, uniform in thickness, and aesthetically pleasing, which is crucial for traffic markings.

- Adjustable Glass Microbead Spreader: Comes with a speed shifting device that allows for the adjustment of the spread width, enhancing the visibility and safety of the markings.

- Rear Wheel Positioner: Guarantees that the machine follows a straight path, which is vital for consistent and accurate line marking.

- Durable and Heat-Resistant Components: Features like a hard tungsten alloy bottom knife and special wear-resistant wheels ensure durability, resistance to high temperatures, and longevity.

- Efficient Bead Spreading: The bead spreading system is synchronized with the paint application, ensuring an even distribution of glass beads for better reflectivity at night.

Applications:

The thermoplastic road marking machine is versatile and can be used in various environments including:

- Highways and Municipal Roads: Suitable for marking driving lanes, pedestrian zones, and other traffic directives.

- Parking Lots: Ideal for demarcating spaces and traffic flow directions in commercial and public parking areas.

- Village or Town Roads: Helps in enhancing road safety and organization in smaller communities.

- Factory Marking: Essential for maintaining operational efficiency and safety in industrial environments.

Additional Characteristics:

- High-Strength Material Construction: Utilizes either plate welding or aluminum die-casting for the bin, which resists high temperatures and deformation while ensuring good heat conduction.

- Electrophoretic Coating or Electroplating: Offers excellent anti-corrosion and anti-rust properties, prolonging the machine’s lifespan.

- Versatility in Line Widths: By changing hoppers of different sizes, it can meet diverse marking width requirements, enhancing its utility for various projects.

Benefits:

- Cost-Effective: Low initial investment and maintenance costs make it a practical choice for budget-conscious entities.

- User-Friendly: Simple operation and easy transportation facilitate quick deployment and use on-site.

- Durability: Built to withstand tough working conditions and high temperatures, ensuring long-term service.

- Precision and Quality: Delivers consistently high-quality and precise road markings, crucial for safety and compliance with traffic regulations.

Specification :

| Tank capacity (kg) | 100KG, Double stainess steel heating insulation barrels,plug-in manually mixer devices, removable devices |

| Glass bead box capacity (kg) | 10kg/box |

| Adjust Glass Beads Dispenser | Synchronous clutch transmission with speed control shifting device, adjustable width 50-200mm |

| Heating method | Liquefied petroleum gas |

| Marking line width (mm) | Standard 150 (optional 50, 100,150, 200, 250, 300 ,400,450) |

| Marking line thickness (mm) | 1-2.5 (adjustable) |

| Knife Underframe | Carbide, with eccentric sleeve device can adjust the 1-2.5mm |

| Tire | Alloy wheel, a special heat-resistant rubber |

| Rear Wheel Directional Device | Ensure the machine moving in straight line or turning freely in curved road |

| Heating temperature | 180-210℃ |

| Dimensions (mm) | 1250X900X950 |

| Weight (kg) | 110 |

Reviews

There are no reviews yet.