Description

Meaning of Different Colors of Reflective Road Studs:

Reflective road studs come in various colors, each designed to convey specific information about the road layout:

- White Reflective Road Marker: These are used to mark the lanes or the middle of the road. They help in maintaining lane discipline, especially on roads that are not well-lit.

- Red Reflective Road Markers: Placed along the left edge of the road, these markers warn drivers not to veer off the carriageway, enhancing safety by delineating the boundary of the road.

- Motorway Amber Studs: These are used to mark the central reservation of dual carriageways or motorways. They play a crucial role in separating different streams of traffic and increasing driver awareness of central barriers.

- Green Reflective Road Marker: Positioned at the edge of the main carriageway at lay-bys and slip roads, these studs signal entry and exit points, aiding in smoother transitions on and off the road.

- Green/Yellow Reflective Road Marker: These indicate temporary adjustments to lane layouts, such as during roadworks. They are crucial for guiding drivers safely around construction zones.

Key Characteristics of Reflective Road Studs:

Reflective road studs are designed to be durable, highly visible, and easy to install. Some of their notable characteristics include:

- Standards Compliance: They meet ASTM D4280 & EN1463-1 standards, ensuring that they are manufactured to high safety and quality specifications.

- Special Texture Design: The studs are designed to bond tightly with the road surface through strong adhesives, providing stability and ensuring they remain in place even under the pressure of passing traffic.

- High Reflectivity: Equipped with micro prism total reflection reflectors, these studs achieve diamond-level brightness. This feature is critical for ensuring they are visible from a distance, even in poor lighting or weather conditions.

- Durability and Longevity: Made using robust materials such as DBM die plates from Canada and PMMA lens technology from Taiwan, these road studs are designed to withstand severe impacts and environmental conditions, making them a long-lasting solution for road safety.

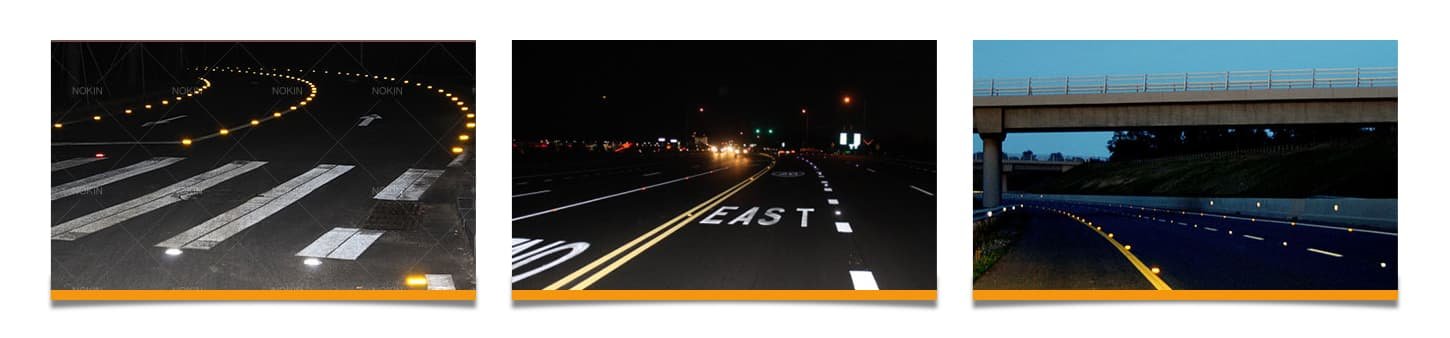

Application and Installation:

When installing reflective road studs, it is important to consider the type of road and the traffic conditions. Plastic road studs are suitable for areas with lower traffic volumes, such as near schools, hospitals, and factories. In contrast, aluminum road studs are recommended for high-speed roads and areas with high volumes of heavy vehicles due to their enhanced durability.

Proper installation involves cleaning the road surface thoroughly before applying a strong adhesive to fix the studs in place. This ensures that the studs remain securely attached to the road, providing continuous safety benefits.

In summary, reflective road studs are critical for enhancing road safety by improving visibility and guiding drivers effectively. By adhering to standards and using advanced materials, these studs provide reliable performance in various traffic conditions and environments.

Specification :

| Model | NK-1005 |

| Material | PC/ABS |

| Reflective material | Impact resistant PMMA |

| Color | Red, Yellow, White, Blue, Green, Red/White |

| Size | 103mm x 80mm x 18mm (4.06″*3.15″*0.71″) |

| Weight | 93g/pc; 10kg/ctn (0.21bs/pc; 22.05bs/ctn ); 100pcs/ctn |

| Compression | 16 T |

Reviews

There are no reviews yet.