Indeed, solar road stud lights represent a significant advancement in road safety technology, primarily due to their ability to withstand harsh environmental conditions while providing consistent, reliable service. The robust design and innovative features of these devices make them particularly well-suited for regions experiencing extreme weather patterns. Here’s an in-depth exploration of how solar road studs maintain their performance across various challenging conditions:

1. Designed for Weather Resistance

- Waterproof Design: Solar road studs often feature IP68-rated enclosures, which are the highest standard for waterproof capabilities. This rating ensures that the studs can handle not just rain but also complete submersion in water, which might occur during heavy floods.

- Temperature Tolerance: Using materials like polycarbonate and aluminum alloys, these studs can endure extreme temperatures ranging from as low as -40°C to as high as 70°C. This versatility is crucial for their functionality in both freezing and scorching conditions.

- UV Resistance: The addition of UV-stabilized coatings protects the studs from solar radiation, which can cause materials to degrade over time. This is especially important in regions with high exposure to sunlight.

2. Performance in Heavy Rain and Flooding

- Sealed Components: These ensure that even during intense rainfall, the internal mechanisms of the studs remain dry and functional.

- Efficient Drainage Systems: Advanced designs include mechanisms that prevent water from pooling around the devices, which could otherwise lead to decreased functionality.

- Non-Slip Surfaces: The surface texture of solar road studs is designed to maintain traction even when wet, reducing the risk of accidents during rainy conditions.

3. Resilience in Snowy and Icy Conditions

- Anti-Freezing Coatings: These coatings prevent the buildup of ice on the surface of the studs, which could obscure the lights and reduce their effectiveness.

- Durable Batteries: The use of lithium-ion batteries that operate efficiently in cold temperatures ensures that the studs remain active, even in harsh winter conditions.

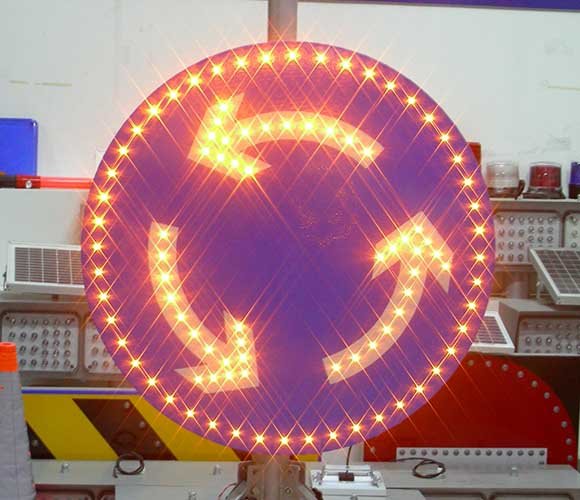

- Enhanced Visibility: High-intensity LEDs are crucial for maintaining visibility during snowstorms, helping to guide drivers safely.

4. Heat Resistance in Arid Regions

- Thermal Management Systems: Materials designed to resist high temperatures prevent the studs from warping or discoloring under the intense heat.

- Overcharge Protection: Safety features protect the battery from overheating, which is a common hazard in hot climates.

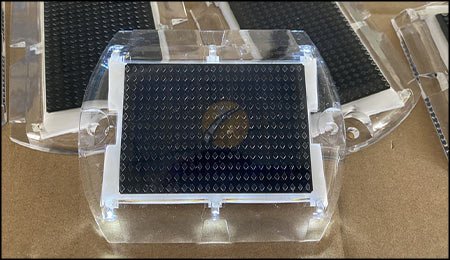

- Reliable Solar Panels: Designed to be efficient even in strong sunlight, these panels ensure that the studs remain powered throughout the day.

5. Withstanding High Winds and Sandstorms

- Durable Anchor Systems: These are essential for keeping the studs in place in areas prone to high winds.

- Robust Outer Shells: The materials used are selected for their ability to resist abrasion, which is particularly important in sandy or dusty environments.

6. Success Stories from Around the World

- Dubai: Here, solar road studs have proven their ability to withstand extreme heat and frequent sandstorms, continuing to function effectively under challenging conditions.

- Norway: Features like anti-freezing coatings are tested in this snowy environment, ensuring that roads remain navigable during the icy months.

- India: The intense monsoon seasons provide a rigorous test of the waterproofing capabilities, with the studs continuing to operate efficiently throughout.

In summary, the design and construction of solar road studs make them exceptionally capable of dealing with a variety of harsh weather conditions. They are a reliable choice for improving road safety across different global climates, providing a sustainable and efficient solution. This resilience, coupled with their environmental benefits, makes solar road studs an excellent investment for future-proofing road safety infrastructures.